Seawall / Bulkhead Repair Case Study Using Deep Foamjection™

Project: Matagorda seawall repair due to deterioration of concrete seawall and bulkhead

Size: Eighty-eight linear feet of seawall.

Time To Complete: 30 hours (a day and a half)

Problem: Concrete Seawall Deterioration in Matagorda

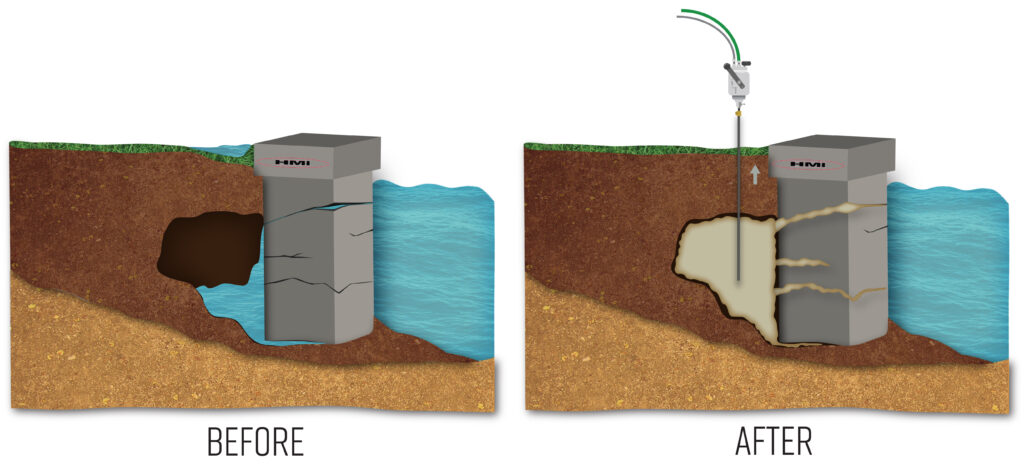

Concrete Alignment Technology (CAT Foam) was contacted by a gentleman who was looking for options to repair his failing concrete seawall for his bay home in Matagorda, TX. The home was located on a canal that connects directly to the Gulf Intracoastal Waterway. The non-stop commercial traffic, consisting of tugboats pushing massive 300-ton steel barges, created a constant displacement of water in the canal which caused the concrete seawall to deteriorate and allow water infiltration. Due to this continuous water movement, the base soil was washed out and voids began to develop below the seawall. Once the support soils were lost, sinkholes or settlement of soils along the seawall became apparent.

Summary: Benefits of Matagorda Seawall Repair with CAT Foam Polyurethane Foam Injection

The homeowner was exploring other solutions such as the replacement of the entire length of the seawall. He was stunned when he received a quote from a local company for just over $34,000 to replace the concrete seawall. Our polyurethane injection process helped the owner avoid the costly hassle of dealing with coastal marine contractors and the time-consuming process of seawall replacement. After the initial walkthrough of the property, the CAT Foam team inspected the area, and it was determined that eighty-eight linear feet of bulkhead were failing and in need of repair.

This saved the customer $24,500, increased the useful life of the seawall structure, and minimal invasiveness of the area receiving treatment.

Solution: Affordable Seawall Repair Delivered On-Time and Within Budget

CAT Foam used the Deep Foamjection™ process to stabilize the soils and prevent further erosion and loss of soil without excavating or damaging the seawall. Deep Foamjection™ is the process of injecting high-density foam to specified depths to reestablish and increase the load-bearing capacity of the soils. The material used for this project was HMI’s expansive polyurethane 402-HydroFoam. HydroFoam was chosen due to its unique hydro-insensitive polymers that aggressively seek out voids and maintain dimensional stability in wet environments.

For this Matagorda seawall repair project, CAT Foam installed twenty-one injection points along the seawall at depths of approximately 3ft and 6ft under the ground. The entire process was completed in a day and a half, and CAT Foam provided a cost-effective solution.

For a free estimate on Matagorda seawall repair or concrete lifting & leveling, call CAT Foam at (800) 595-1880